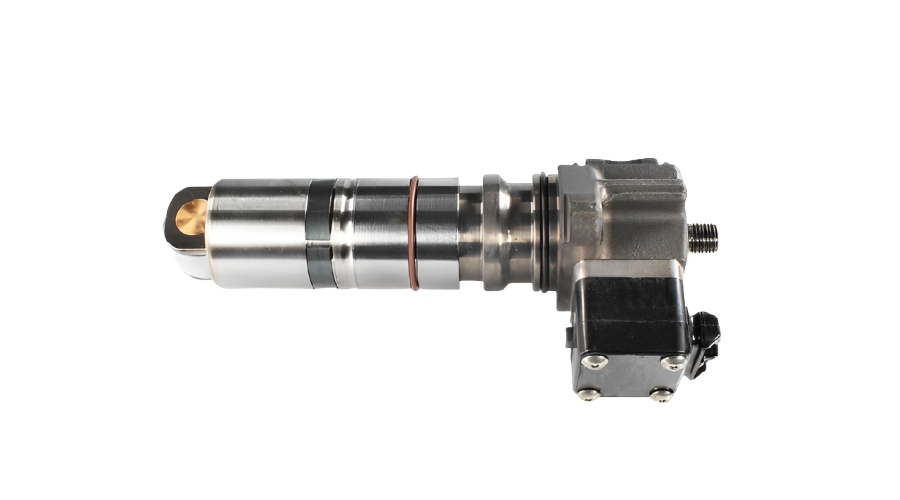

A0280745902 for Mercedes Benz MBE4000 Unit Pump, New (P274520)

September 13, 2025

AR74664 for John Deere Tractor/Combine/Harvester Fuel Injector Nozzle

September 13, 2025A0280748802 | Mercedes Benz MBE900 Unit Pump, New (RA0280748802)

Key Information

Part Number: 0-414-799-018, 0-414-799-024, 0-986-445-022, 0280748802, 0414799018, 0414799024, 0986445022, 280748802, A0280748802, F-00E-200-413, F00E200413, RA0280748802

Engine Make: Mercedes Benz

Inspection Report: Yes

Warranty: 17 Months

Supply Ability: In stock

Payment Way: Paypal, Western Union, Visa, Mastercard, T/T

Details: One model in a neutral box or specific box required by clients.

The part number A0280748802 to correspond to a unit pump for the Mercedes-Benz MBE900 series of engines. The MBE900 is a common heavy-duty diesel engine used in trucks and industrial applications.

Key Details:

-

Application: Mercedes-Benz MBE900 (also used in some Freightliner and Detroit Diesel applications).

-

Function: The unit pump is part of the fuel injection system, delivering high-pressure fuel to the injectors.

-

Compatibility: Verify with your engine’s exact model and serial number, as variations exist.

Alternative/OEM Cross-References:

-

OEM Numbers:

-

Mercedes-Benz: 0280748802 (without the “A” prefix)

-

Detroit Diesel: 23518434 (possible equivalent)

-

a. Housing & Material Construction

-

Material: Typically made from high-strength alloy steel or forged steel to withstand extreme pressures (up to 1,800–2,200 bar in some systems).

-

Precision Machining: Critical surfaces (e.g., plunger bore, cam follower) are hardened and ground for durability and smooth operation.

-

Sealing: Uses high-pressure O-rings and gaskets to prevent fuel leaks.

-

b. Internal Components

-

Plunger & Barrel Assembly:

-

The plunger is driven by the engine’s camshaft via a roller tappet.

-

Precision-matched to ensure minimal fuel leakage and maximum pressure buildup.

-

Solenoid Valve (if electronically controlled):

-

Regulates fuel delivery timing and quantity based on ECU signals.

-

Return Spring:

-

Ensures the plunger resets after each stroke.

-

c. Fuel Inlet/Outlet Ports

-

Low-pressure inlet: Receives fuel from the supply pump.

-

High-pressure outlet: Delivers fuel to the injector via a high-pressure line.

-

2. Strengths & Advantages

-

The MBE900 unit pump is designed for reliability, efficiency, and performance in heavy-duty applications.

-

a. High Durability

-

Robust construction resists wear from continuous high-pressure operation.

-

Hardened components (e.g., cam follower, plunger) extend service life.

-

b. Precision Fuel Delivery

-

Mechanical/electronic control ensures accurate metering for optimal combustion.

-

Consistent pressure output improves engine efficiency and reduces emissions.

-

c. Simplified Maintenance

-

Modular design allows individual replacement (unlike unit injectors, which are more integrated).

-

Easier troubleshooting compared to common-rail systems in some cases.

-

d. Compatibility & Adaptability

-

Works with different MBE900 variants (e.g., 4.8L, 7.2L, 8.3L).

-

Used in Mercedes-Benz, Freightliner, and Detroit Diesel applications.

The unit pump is a mechanically actuated, high-pressure fuel pump that works with the engine’s electronic control system (ECU) to deliver precise fuel amounts to each cylinder.

| Parameter | Specification |

|---|---|

| Part Number | A0280748802 / 0280748802 |

| Engine Compatibility | MBE900 (4.8L, 7.2L, 8.3L) |

| Type | Mechanically actuated, solenoid-controlled unit pump |

| Maximum Pressure | 1,800 – 2,200 bar (26,100 – 31,900 psi) |

| Material (Housing) | High-strength alloy steel / forged steel |

| Plunger Type | Precision-ground hardened steel |

| Actuation | Camshaft-driven (via roller tappet) |

| Control System | ECU-controlled solenoid valve |

| Fuel Inlet Pressure | 4 – 6 bar (58 – 87 psi) (from supply pump) |

| Weight (approx.) | ~3 – 5 kg (varies by model) |

| Sealing Components | High-pressure O-rings, gaskets |

| Common Failure Modes | Plunger wear, solenoid failure, fuel contamination |

| Service Life | 500,000 – 1,000,000 km (with proper maintenance) |

Related products

-

22378579 Diesel Fuel Injector for Mack and Volvo MP8/D13 engine

Engine Make: Volvo

Inspection Report: Yes

Warranty: 12 Months

-

414799012 Unit Pump for Mercedes Benz MBE900

Engine Make: Mercedes Benz

Inspection Report: Yes

Warranty: 12 Months

-

5226575 | Detroit Diesel 9A31/DDC Fuel Injector

Engine Make: Detroit

Inspection Report: Yes

Warranty: 12 Months