Detroit Diesel 8.2L (Fuel Injector â Part #5226280)

September 13, 2025

Detroit Diesel Series 60 Fuel Injector (Part #05237026)

September 13, 2025Detroit Diesel Series 60 Fuel Injector (05237099)

Key Information

Part Number: 05237099, 1480200046, 5237099, 5237099DDCR, 5237099R, 5237099X, 637099, EX637099, F00E200252, FS5237099, R-5237099, R5237099, RB5237099

Engine Make: Detroit

Inspection Report: Yes

Warranty: 12 Months

Supply Ability: In stock

Payment Way: Paypal, Western Union, Visa, Mastercard, T/T

Details: One model in a neutral box or specific box required by clients.

Detroit Diesel Series 60 Fuel Injector (05237099)

-

Application: Used in Detroit Diesel Series 60 engines, which were commonly found in heavy-duty trucks, buses, and industrial applications.

-

Function: Delivers precise amounts of fuel into the combustion chamber at high pressure for efficient engine performance.

-

Compatibility:

-

Fits various Series 60 engine models (12.7L & 14L variants).

The Detroit Diesel Series 60 fuel injector (Part #05237099) is a critical component in the fuel injection system of the Series 60 engine, a heavy-duty diesel engine widely used in commercial trucks, buses, and industrial applications. Below is a breakdown of its structure and application scenarios:

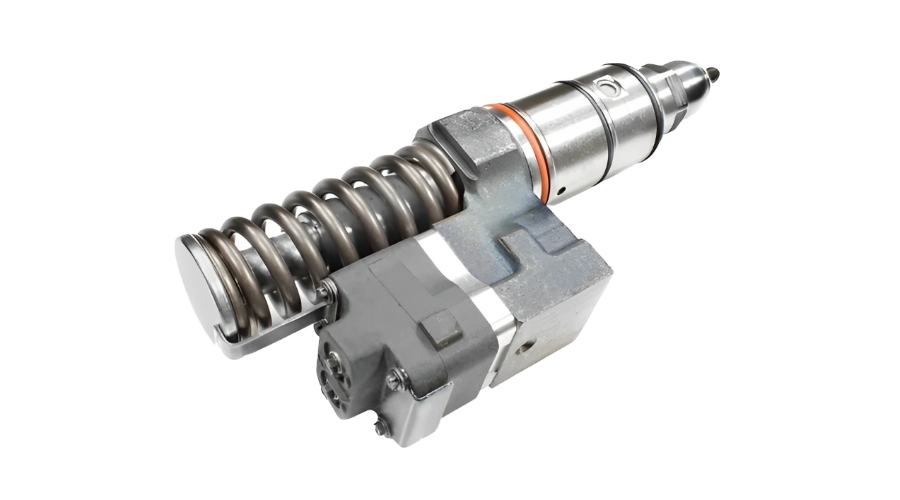

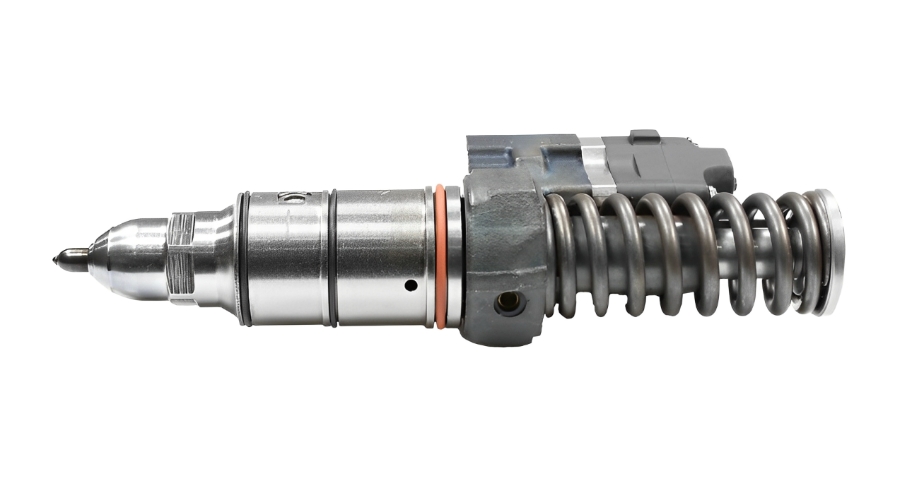

Structure of the Detroit Diesel Series 60 Fuel Injector (05237099)

The fuel injector is a precision-engineered electromechanical (or hydromechanical, depending on the variant) device that delivers atomized fuel into the combustion chamber. Its key components include:

Nozzle Assembly

-

Contains a precision-machined tip with tiny orifices for fuel atomization.

-

Opens at high pressure (typically 3,000–5,000 psi in mechanical injectors, higher in electronic versions).

Injector Body

-

Houses the needle valve that controls fuel flow.

-

Made of hardened steel to withstand high-pressure cycles.

Solenoid (if electronically controlled)

-

In later DDEC (Detroit Diesel Electronic Control) versions, an electromagnetic solenoid controls injection timing.

Spring & Pressure Adjustment Mechanism

-

A spring-loaded needle valve ensures proper opening/closing pressure.

-

Adjustable in some mechanical injectors for calibration.

Fuel Inlet & Return Ports

-

High-pressure fuel enters through the inlet.

-

Excess fuel returns via the return line to maintain pressure balance.

O-Rings & Seals

-

Prevent fuel leaks and maintain pressure integrity.

Application Scenarios

The Series 60 fuel injector (05237099) is used in heavy-duty diesel engines in the following applications:

1. Commercial Trucking (Long-Haul & Vocational)

-

Freightliner, Kenworth, Peterbilt, Volvo, Mack trucks with Series 60 engines.

-

Ensures fuel efficiency, power, and emissions compliance (especially in pre-2007 engines before ultra-strict EPA standards).

2. Public Transportation (Buses)

-

Used in transit buses (e.g., MCI, Gillig, Nova Bus) with Detroit Diesel Series 60 engines.

-

Provides smooth operation and reliability for stop-and-go driving.

3. Industrial & Marine Applications

-

Found in generator sets, construction equipment, and marine propulsion.

-

Must withstand continuous high-load operation.

4. Military & Emergency Vehicles

-

Some military trucks and fire/rescue vehicles use Series 60 engines for durability and torque.

Here's a summarized technical specifications table for the Detroit Diesel Series 60 Fuel Injector (Part #05237099):

| Parameter | Specification |

|---|---|

| Part Number | 05237099 |

| Engine Compatibility | Detroit Diesel Series 60 (12.7L & 14L) |

| Injector Type | Mechanical (non-electronic) / Hydraulic |

| Nozzle Type | Multi-orifice (hole-type) |

| Operating Pressure | 3,000 – 5,000 psi (207 – 345 bar) |

| Spray Pattern | Precision conical spray for optimal combustion |

| Flow Rate | Varies by calibration (typically ~200–300 cc/min at rated pressure) |

| Thread Size | M12 or M14 (varies by model) |

| Torque Specification | 35–45 lb-ft (47–61 Nm) (verify per service manual) |

| Seal Type | Viton or Nitrile O-rings (high-temp resistant) |

| Weight | ~1.5 – 2.5 lbs (0.7 – 1.1 kg) |

| Expected Lifespan | 300,000 – 500,000 miles (with proper maintenance) |

| Common Failures | Clogged nozzles, worn needle valves, leaking seals |

Related products

-

0445110434 Bosch injector commonly used in various European vehicles

Engine Make: BOSCH

Inspection Report: Yes

Warranty: 12 Months

-

Diesel Fuel Injector Nozzle 0950006410 for Toyota Hilux D4d 2.5 D 2kd-Ftv

Engine Make: Denso

Inspection Report: Yes

Warranty: 12 months

-

Bosch fuel injector 0445110808 for diesel engine parts

Engine Make: BOSCH

Inspection Report: Yes

Warranty: 12 Months