Detroit Diesel Series 60 Fuel Injector (05237099)

September 13, 2025

Diesel injector 0445110367 fuel injector E048632000009 for Bosch

September 13, 2025Detroit Diesel Series 60 Fuel Injector (Part #05237026)

Key Information

Part Number: 05237026, 148-020-0044, 1480200044, 5237026, 5237026DDCR, F00E200249, R5237026, RB5237026

Engine Make: Detroit

Inspection Report: Yes

Warranty: 12 Months

Supply Ability: In stock

Payment Way: Paypal, Western Union, Visa, Mastercard, T/T

Details: One model in a neutral box or specific box required by clients.

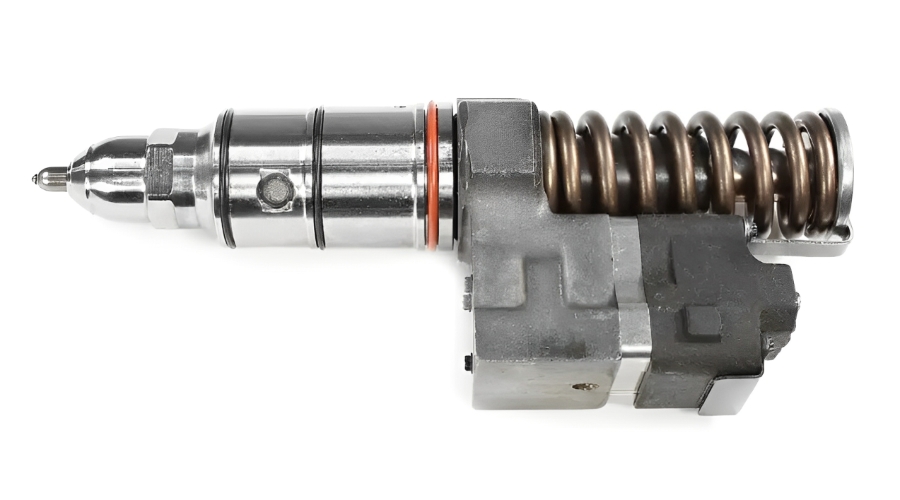

Detroit Diesel Series 60 Injector (05237026)

-

Application: Used in Detroit Diesel Series 60 engines (likely for 11.1L, 12.7L, or 14L variants).

-

Function: Delivers precise fuel injection for optimal combustion and performance.

-

Compatibility: Verify with your engine’s exact model and year, as injectors may vary by emissions standards (e.g., pre-EGR vs. EGR engines).

The Detroit Diesel Series 60 fuel injector (Part #05237026) is an electronically controlled unit injector (EUI), a critical component in the high-pressure fuel injection system. Below is a breakdown of its structure and key components:

-

1. Main Components of the Series 60 Fuel Injector (EUI)

-

A. Solenoid Valve Assembly

-

Function: Controls fuel injection timing and duration via signals from the ECM (Engine Control Module).

-

Components:

-

Solenoid coil: Electromagnet that opens/closes the injector needle.

-

Armature plate: Moves to actuate the needle valve.

-

Electrical connector: Receives ECM signals.

-

B. Injector Body

-

Material: High-strength steel to withstand combustion pressures (up to 30,000 psi in later models).

-

Fuel passages: Directs high-pressure fuel from the pump to the nozzle.

-

C. Plunger and Barrel Assembly

-

Function: Generates high-pressure fuel by reciprocating motion (driven by the engine’s camshaft via rocker arms).

-

Precision-matched: The plunger and barrel are lapped together to prevent fuel leakage.

-

D. Nozzle Tip (Spray End)

-

Design: Multi-hole nozzle (typically 6–8 holes) for fine fuel atomization.

-

Check valve: Ensures sharp injection cutoff to prevent dribbling.

-

Tapered seat: Seals against combustion chamber pressure.

-

E. Return Spring

-

Role: Returns the plunger and needle valve to the closed position after injection.

-

F. Fuel Inlet/Outlet Ports

-

Low-pressure inlet: Receives fuel from the supply line.

-

High-pressure circuit: Internal passages route fuel to the plunger chamber.

-

Leak-off return: Excess fuel returns to the tank to cool the injector.

-

2. How It Works (Operation Cycle)

-

Fuel Delivery: Low-pressure fuel enters the injector from the fuel rail.

-

Solenoid Activation: The ECM sends a pulse to the solenoid, lifting the needle valve.

-

High-Pressure Creation: The camshaft-driven plunger pressurizes fuel (up to 25,000–30,000 psi).

-

Injection: Pressurized fuel sprays through the nozzle into the cylinder.

-

Cutoff: Solenoid de-energizes, and the spring closes the needle valve.

-

3. Critical Design Features

-

Electrohydraulic Operation: Combines electronic control with mechanical pressure generation.

-

Integrated Design: Unlike common-rail systems, the Series 60 EUI generates high pressure internally.

-

Durability: Hardened materials resist wear from abrasive ultra-low-sulfur diesel (ULSD).

Here's a summarized technical specification table for the Detroit Diesel Series 60 Fuel Injector (Part #05237026):

| Parameter | Specification |

|---|---|

| Part Number | 05237026 |

| Engine Application | Detroit Diesel Series 60 (11.1L, 12.7L, 14L variants) |

| Type | Electronically Controlled Unit Injector (EUI) |

| Injection Pressure | 23,000 – 30,000 psi (varies by engine calibration) |

| Nozzle Type | Multi-hole (typically 6–8 holes) |

| Solenoid Voltage | 12V DC (ECM-controlled pulse signal) |

| Flow Rate | Varies by calibration; typically ~200–400 mm³/stroke (depends on ECM settings) |

| Torque Specification | 35–45 lb-ft (for mounting bolts, varies by model) |

| Fuel Compatibility | Ultra-Low Sulfur Diesel (ULSD) |

| Operating Temp. | -40°C to +150°C (-40°F to +302°F) |

| Weight | ~2.5–3.5 lbs (varies by design) |

| Key Material | Hardened steel (plunger/barrel), copper alloy (seats), solenoid coil (copper) |

| Service Life | 500,000–750,000 miles (with proper maintenance) |

Related products

-

Bosch fuel injector 0445110257 for engine model D4EA

Engine Make: BOSCH

Inspection Report: Yes

Warranty: 12 Months

-

Fuel injector 0445110312 for engine model ADCR110

Engine Make: BOSCH

Inspection Report: Yes

Warranty: 12 Months

-

22378579 Diesel Fuel Injector for Mack and Volvo MP8/D13 engine

Engine Make: Volvo

Inspection Report: Yes

Warranty: 12 Months